Ridge Capping Plain Ridge Machine

$14500≥1Set/Sets

| Payment Type: | L/C,T/T,D/P,cash |

| Incoterm: | FOB,EXW,CIF,CFR,DDP,DDU |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

$14500≥1Set/Sets

| Payment Type: | L/C,T/T,D/P,cash |

| Incoterm: | FOB,EXW,CIF,CFR,DDP,DDU |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

Model No.: XF Plain Ridge Cap Machine

Brand: XF

Applicable Industry: Building Material Shops

Out-of-warranty Service: Online Support, Spare Parts, Video Technical Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Machine Type: Tile Forming Machine

Tile Type: Steel

Use: Roof

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Rolling Thinckness: 0.3-0.8mm

Feeding Width: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Plc

Name: Roof Ridge Cap Roll Forming Machine

Product: Roof Tile Ridge Cap

Productivity: 15 M/Min

Marketing Type: Ordinary Product

| Selling Units | : | Set/Sets |

| Package Type | : | Main machine is nude,the computer control box is packed by wooden carton box. |

| Picture Example | : |

|

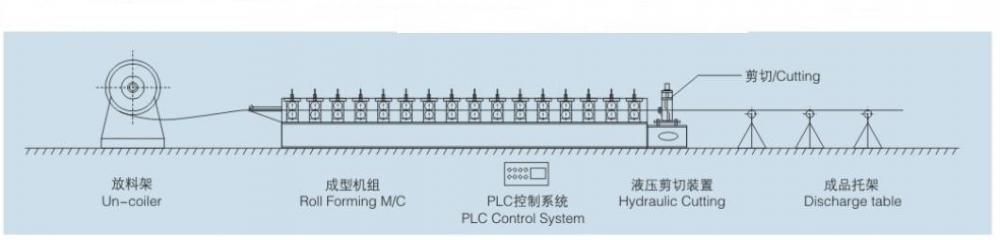

A metal Ridge Cap Forming Machine is a specialized equipment used for manufacturing metal ridge caps. It consists of several components that work together to shape and form the metal material into desired ridge cap profiles. The main components and their functions are as follows:

Decoiler: This component holds the metal coil, which is the raw material for the ridge tiles. It feeds the metal strip into the machine for further processing.

Feeding system: The feeding system accurately moves the metal strip through the machine, ensuring precise positioning and alignment for consistent ridge tile production.

Roll forming station: This station contains a series of rollers and tooling sets that gradually shape the metal strip into the desired ridge tile profile. The rollers apply pressure and bending forces to deform the metal strip according to the specific design.

Cutting system: Once the metal strip has been formed into the desired ridge tile shape, the cutting system trims the excess material and separates the individual ridge tiles. This can be achieved through various cutting methods such as hydraulic shearing or flying saw blades.

Control system: The control system manages and regulates the entire operation of the machine, including speed control, length measurement, and synchronization of different components. It ensures accurate and efficient production.

The main function of the metal ridge tile forming machine is to transform a metal coil into ridge tiles with specific shapes, dimensions, and profiles. By passing the metal strip through the roll forming station, it undergoes a series of shaping processes to achieve the desired ridge tile design. The machine's precision and consistency in forming the metal material result in high-quality ridge tiles suitable for roofing applications.

Metal ridge tile forming machines can be classified into various categories based on different criteria. Here are some common classifications of metal ridge tile forming machines: Based on the type of ridge tile: Based on the material used: Based on the production capacity: Based on the design complexity: Based on additional features: These classifications help categorize metal ridge tile forming machines based on their intended use, capabilities, and specifications. Manufacturers can choose the most suitable machine based on their production needs and desired ridge tile specifications.

Industrial Process And Component Specification

Botou Xianfa Roll Forming Machine Factory

Welcome to contact with me

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.