C Z Purlin Roll Forming Machine

$63500-65500 /Set/Sets

| Payment Type: | T/T,L/C,Western Union,CASH |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

$63500-65500 /Set/Sets

| Payment Type: | T/T,L/C,Western Union,CASH |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

Model No.: XF CZ Purlin Forming Machine

Brand: Xianfa

Applicable Industry: Building Material Shops

Out-of-warranty Service: Online Support, Spare Parts, Video Technical Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Machine Type: Tile Forming Machine

Tile Type: Steel

Use: Roof

Productivity: 15 M/Min

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Rolling Thinckness: Other

Feeding Width: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc

| Selling Units | : | Set/Sets |

| Package Type | : | Main machine is nude,the computer control box is packed by wooden carton box. |

| Picture Example | : |

|

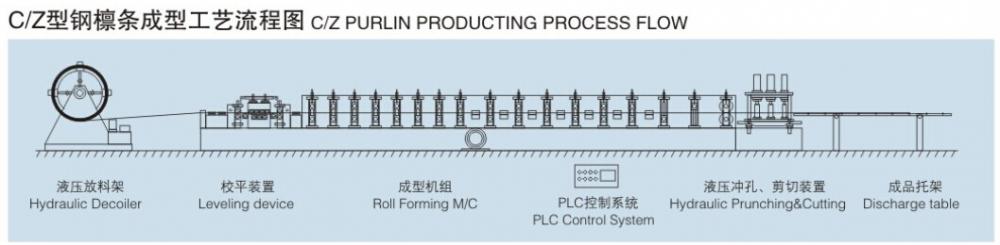

CZ Type Purlin Machine - Technical Specifications and Advantages

The Roof Purlin Machine is a versatile Roll Forming Machine that is specifically designed for producing CZ steel purlins. It combines the capabilities of both C Purlin Machine and Z Purlin roll forming machines, offering several advantages over using these machines separately.

Technical Specifications:

Material Compatibility: The CZ Purlin Machine can work with various materials, including galvanized steel, cold-rolled steel, and hot-rolled steel.

Forming Speed: It has a high production speed, typically ranging from 10 to 25 meters per minute, depending on the specific model and configuration.

Size Range: The Purlin Roll Forming Machine can produce purlins in a wide range of sizes and profiles, accommodating different project requirements. Common sizes include C80-C300 and Z100-Z300.

Thickness Range: It can handle material thicknesses ranging from 1.5mm to 3.0mm, ensuring flexibility in design and application.

Automatic Control System: The CZ Purlin Machine is equipped with an advanced PLC control system, allowing for easy operation and precise control over various parameters.

Cutting Mechanism: It employs a flying cutting system or a hydraulic cutting system, ensuring accurate and efficient cuts without compromising the overall production speed.

Roll Forming Process: The machine utilizes a continuous roll forming process, which ensures uniform and high-quality purlin production with consistent dimensions and shapes.

Advantages over Separate C and Z Purlin Machines:

Cost-effectiveness: By combining the functionalities of C and Z Purlin machines, the CZ Purlin Machine offers a more cost-effective solution for producing both types of purlins. It eliminates the need for investing in multiple machines and reduces labor costs.

Flexibility: The CZ Purlin Machine allows for easy and quick adjustment between C and Z purlin production, providing greater flexibility in meeting different project requirements.

Space-saving: Instead of having separate machines for C and Z purlins, the CZ Purlin Machine occupies less space in the factory or workshop, optimizing the utilization of available space.

Improved Efficiency: The CZ Purlin Machine's high-speed production capability ensures efficient manufacturing, reducing production time and increasing overall productivity.

Overall, the CZ Purlin Machine offers remarkable technical specifications and advantages by combining the functionalities of C and Z Purlin machines. It provides cost-effectiveness, flexibility, space-saving, and improved efficiency, making it a preferred choice for producing CZ steel purlins in various construction projects.

Industrial Process And Component Specification

1. Manual Uncoiler:

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 3T

2. Feeding and Leveling Device:

It is used for making the material flat before feeding into the roll forming machine. 11 rollers (five upper and six lower)

3. Rolling Forming System:

Main motor type: frequency motor

Motor power: 18. 5KW

Drive: chain

Speed of forming: 8-15m/min(exclude cutting time)

Material of roller: GCr15

Motor for width adjusting: 2.25KW(0.75KW*3)

Material of main shaft: 40Cr (the main shaft have the high frequency grinding & heat Treatment and the surface of shaft is chroming)

4. Hydraulic System:

Punching type: hydraulic punching

Cutting type: hydraulic cutting (we have the patent technology, because our post cutting can be adjustable from 80-300mm)

Cutting material: Cr12 MoV

Hydraulic motor power: 5.5KW

Hydraulic pressure: 16Mpa

Packaging & Shipping

1. We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

Our Services

1. Warranty

One year,and we will provide technical support for wholelife of the equipment.

2. Installation And Charge

Purchaser pays all charges during period of install to overseas,

(include charges of food,lodging and round trip air tickets ,etc.)

Moreover,pay subsidy 60USD/day until Installation finished.

If problems happened out of warranty and need debugging overseas

Customer should pay for all the charges (including food,lodging and round trip air tickets etc.)

Moreover pay 100USD/day till install finished

Recently,our products have been exported to more than 80 countries and regions over the world

and maintained good cooperative relations with customers

We do firmly believe in technological innovation and making every detail of the product perfect is our ambition ever

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.