Double Layer Forming Machine for O100 and R101

$18000≥1Set/Sets

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Tianjin New Port |

$18000≥1Set/Sets

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Tianjin New Port |

Model No.: XF 19-25-1220 Double Layer Forming Machine

Brand: XF

Applicable Industry: Building Material Shops

Out-of-warranty Service: Spare Parts, Online Support, Video Technical Support, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Machine Type: Tile Forming Machine

Tile Type: Steel

Use: Wall

Productivity: 15 M/Min

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Rolling Thinckness: 0.3-0.8mm

Feeding Width: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc

Material Of Rollers: 45# Steel

Certification: ISO

Usage: Wall

Tile Type: Colored Steel

Condition: New

Customized: Customized

Transmission Method: Hydraulic Pressure

Control System: PLC Control

Suitable To Process: Color Steel Plate

Machine Name: Double Layer Forming Machine

Type: Use Roofing Tile

| Selling Units | : | Set/Sets |

| Package Type | : | We have professional technicians for loading Guaranteed the goods load into container without any damage. |

| Picture Example | : |

|

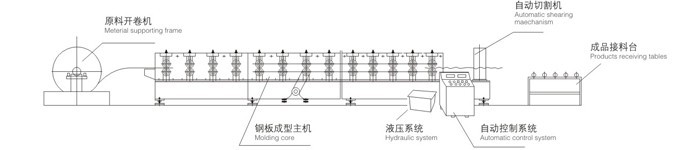

Double Layer Roll Forming Machine for Mexico. The downlayer is Trapezoidal Roll Forming Machine, also named R101 profile forming machine. The upper layer is Corrugated Roll Forming Machine, also named O100 profile forming machine. The feeding material of Roll Forming Machine is 1220mm/0.3-0.6mm. The power of Double Layer Sheet Roll Forming Machine is 4+4Kw.

Double Layer Forming Machine for O100 and R101

This double layer forming machine could process O100 profile sheet and R101 Profile sheet.

They just let O100 corrugated metal sheet Roll Former and R101 Metal Panel Sheet Roll Former make into one machine.

O100 metal panel sheet and R101 metal panel sheet is popular for Mexico market.

We export all kinds of metal profile sheet machine all over the world. If you have the drawing of machine, pls contact me directly, or we also could recommend machine for your country market.

Industrial Process And Component Specification

Manual Uncoiler

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5 Tons, Inner diameter: 470-530 mm

Feeding Table

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat.

Parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Main Roll Forming Machine

Material of rollers: 45# steel, roller surfaces polishing, hard plating.

The polished surface and the heat treatment towards the molds also can keep the molding.

Plate surface smooth and not easy to be marked when it is being stamped

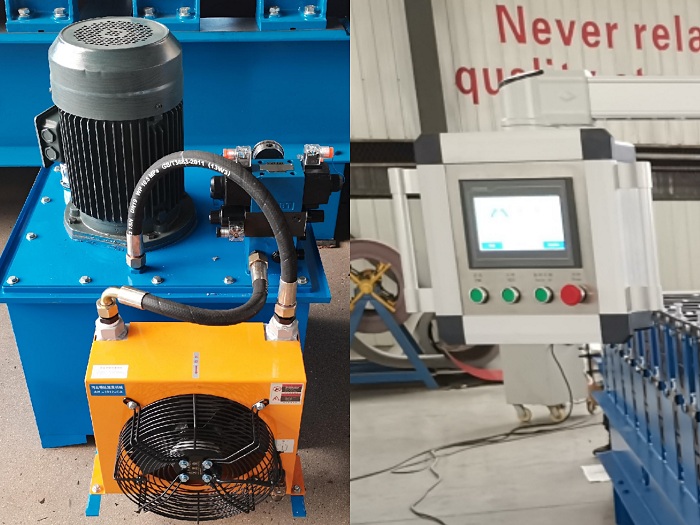

Hydraulic and Control Systems

Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC: Delta Touch Screen

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12, quenching treatment.

Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Packaging & Shipping

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.