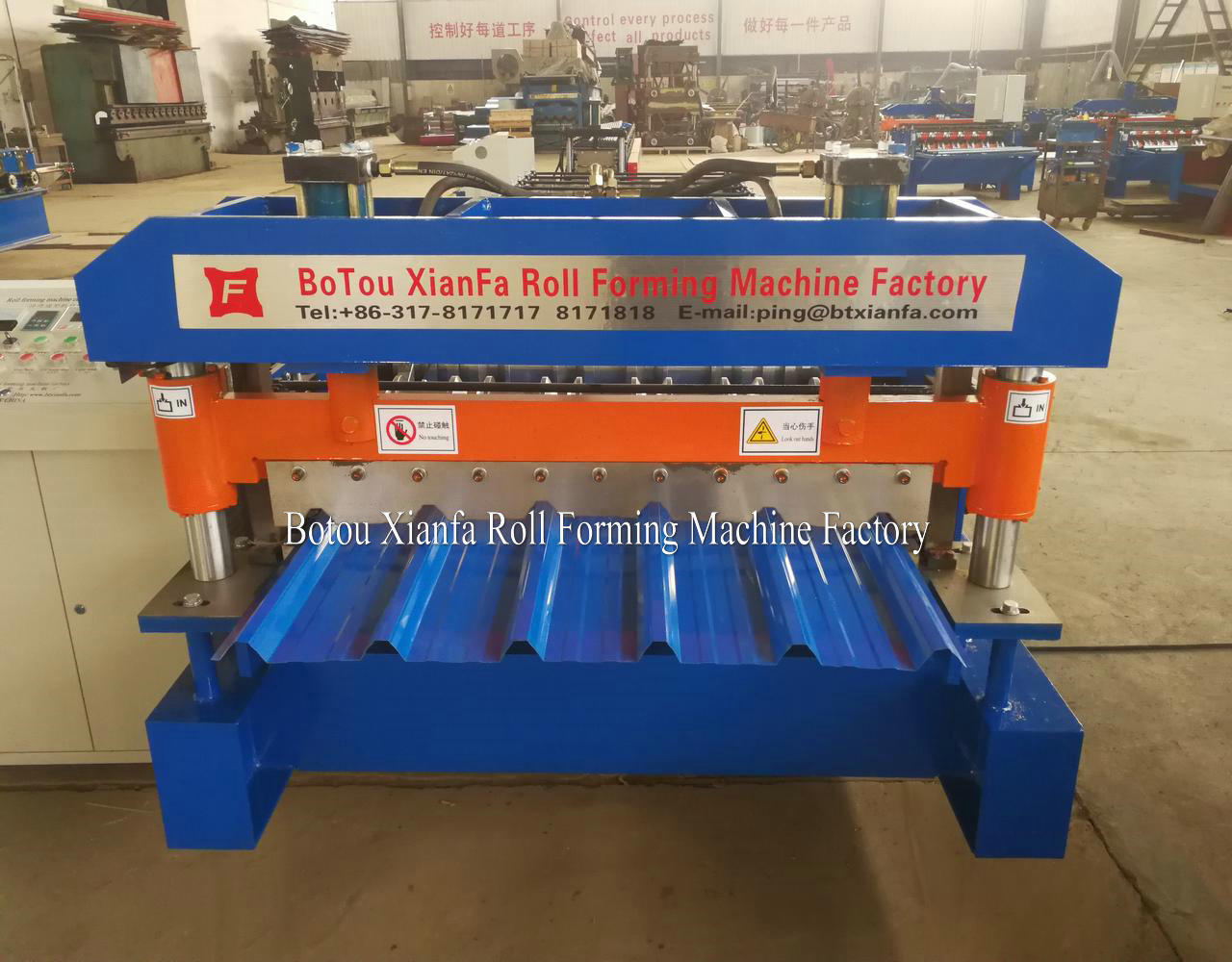

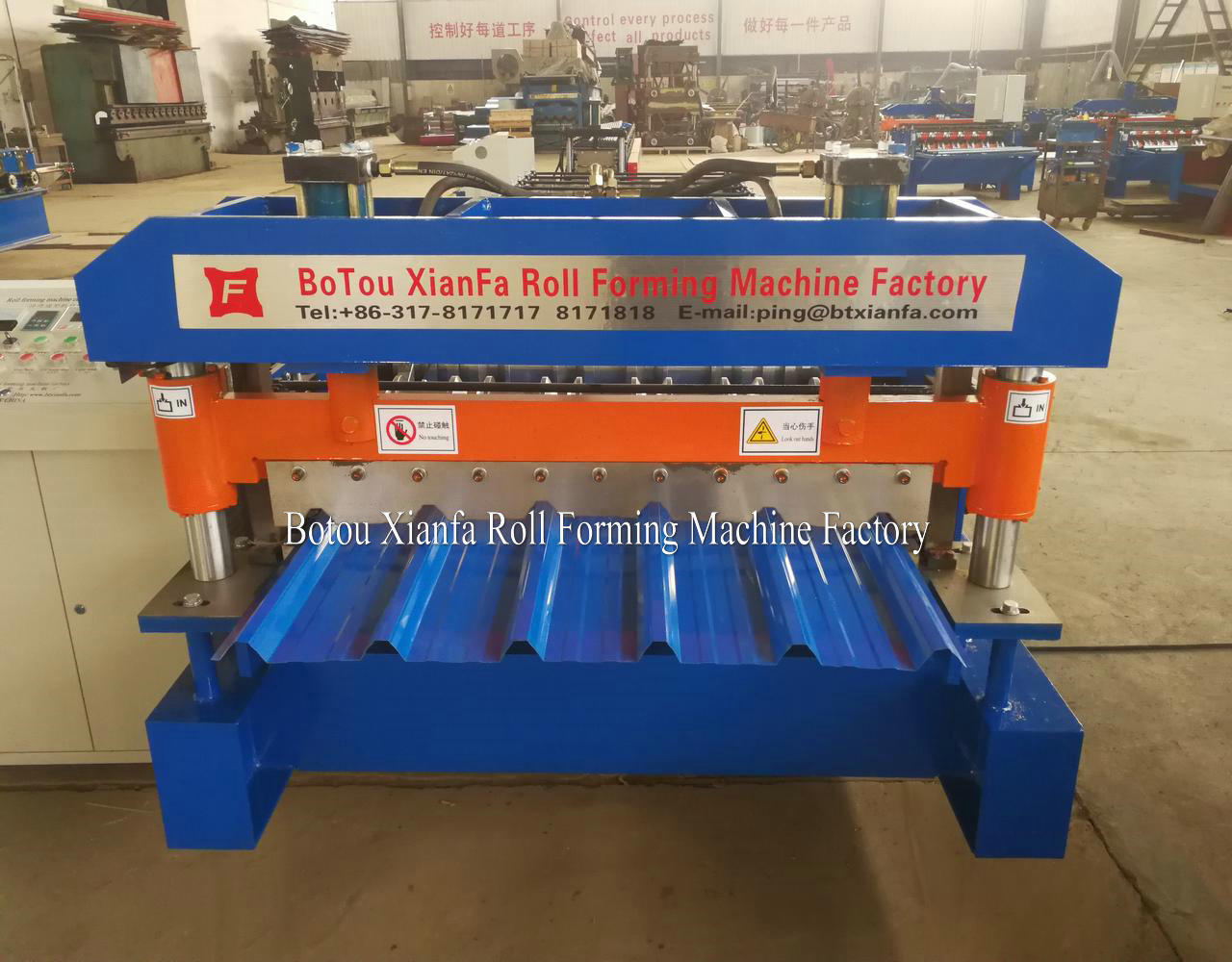

metal roof roll forming machine

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Tianjin New Port |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Tianjin New Port |

Model No.: XF23 roof roll forming machine

Brand: XF

Certification: ISO

Usage: Other

Tile Type: Glazed Steel

Condition: New

Customized: Customized

Transmission Method: Hydraulic Pressure

Suitable To Process: Color Steel Plate

Thickness Of The Plate: 0.3-0.7mm

Scissors Material: CR12

Machine Name: Roll Forming Machine

Machine Type: Roofing Roll Forming Machine

Name: Metal Roof Roll Forming Machine

Type: Roof Roll Forming Machine

| Selling Units | : | Set/Sets |

| Package Type | : | We have professional technicians for loading Guaranteed the goods load into container without any damage. |

metal Roof Roll Forming Machine

metal sheet roof Roll Forming Machine,step Tile Roof Roll Forming Machine,mobile arch roof roll forming machine

Quick Detail

1.Suitable to process: Color steel plate

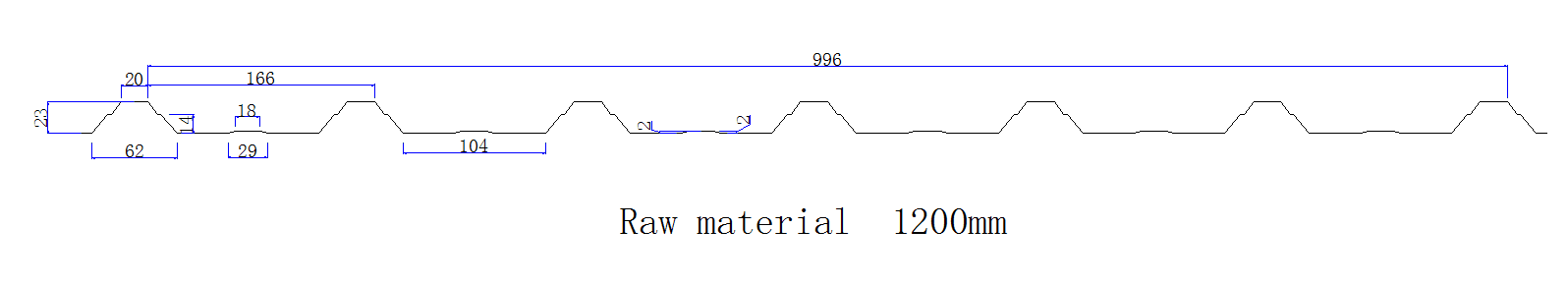

2.Width of the plate: 1200mm

3.Rollers: 13rows

4.Dimensions: 6.7*1.55*1.51m

5.Power: 4+4kw

6.Thickness of the plate:0.3-0.6mm

7.Diameter of the roller:Φ70mm

8.Weight: About 3.5T

9.Voltage: 380V 50Hz 3phases

10.Hydraulic: 40#

11.Processing precision: Within 1.00mm

12.Control system: PLC control

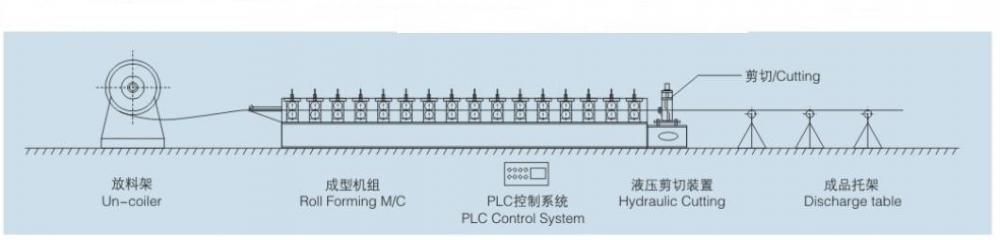

Industrial Process And Component Specification

Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:5000KG.Inner diameter: 500-508mm

Roller

Material of rollers:45# steel,roller surfaces polishing, hard plating

The polished surface and the heat treatment towards the molds also can keep the molding

plate surface smooth and not easy to be marked when it is being stamped.

Hydraulic and Control Systems

Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC: EURA(Can customize as customer require)

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Packaging & Shipping

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 20 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you

looking for ideal Roll Forming Machine Manufacturer and supplier

We have a wide selection at great prices to help you get creative.

All the Roll Forming Machine are quality guaranteed.

If you have any question, please feel free to contact us

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.